Contaminated and high sulphur fuel

Modern European engines aren’t designed to run on high sulphur fuel. In fact they need very low sulphur diesel fuels, typically less than 15 parts per million (PPM). However, there are still some parts of the world with sulphur levels in excess of 5000 PPM! See in the following link:

https://www.unenvironment.org/resources/report/global-sulphur-levels

I have therefore done a bit of research on the effect of sulphur on the engine.

High sulphur fuel is a great lubricant for the fuel pumps, but when it gets into the engine oil it breaks down the oil’s lubricating properties, potentially leading to engine damage. It gets into the oil during the power stroke as a little of the fuel gets blown past the piston rings. This effect is increased during the Diesel Particulate Filter (DPF) regeneration cycle when the fuelling is modified to increase the exhaust temperature. The extra sulphur also increases the rate of clogging of the DPF. If the Daily 4×4 is operated with fuels exceeding 0.5% (5000 ppm) sulphur, then the oil change interval must be halved.

The engine Electronic Control Unit (ECU) monitors the clogging of the DPF by measuring the pressure in the exhaust before and after the DPF. Once the ECU has calculated that the DPF is clogged to a certain level, it will try to burn off the particles thereby clearing the filter. This is done by injecting a little extra fuel after the power stroke; the extra fuel raises the exhaust temperature to 630°C, thereby burning off the particles. This is normally done while the engine is running at high speed on motorway-type driving. If the vehicle does not get up to speed very often (e.g. town driving) the engine is sometimes unable to regenerate the DPF. If this happens, the action must be initiated by an Iveco dealer using the EASY diagnostic computer.

The ECU measures all of these regenerations as they lead to an increase of sulphur in the oil, and based on this it will decide when the oil must be changed. It should always be changed after a manually forced regeneration. This is also why oil changes need the use of the EASY computer to reset the counter in the ECU.

Update – Since writing the above section I have now found a procedure to reset the oil counter and perform a DPF regeneration without a diagnostic computer – see Daily 4×4: Useful information

What to do about high sulphur fuel?

Unfortunately the areas of Africa through which we intend to travel, tend to have fuels with particulate specifications far in excess of the levels allowed in Europe. I am therefore fully expecting that this is likely to be a problem to resolve at some point on our trip! I have been doing further research and asking questions of people who have taken Euro 4/V engine vehicles to the third world.

One precaution I have taken is to select the “other areas” fuel system. This basically removes the lift pump from the fuel tank and puts it in a more accessible place with an extra pre-filter on the chassis. This extra pre-filter is working on the suction side of the pump so it is a little more efficient at separating any water in the fuel. It is also heated and has a water detector and water/sediment drain, the same as the main filter.

Iveco’s advice is simply to buy a vehicle with an engine suited for use with the high sulphur fuel in the relevant country. However this isn’t very helpful for Europeans as you cannot import these vehicles into your home country to register before setting out on your trip! From what I have read, the Daily 4×4 is pretty good at regenerating; it is designed to do this even when the vehicle is not traveling at speed. This is because the engine is expected to be working whilst stationary, powering equipment with one of its many power take-offs.

In 2012 we spoke to a Swiss couple who had travelled throughout South America with a new Mercedes Sprinter 4×4. They had to be towed to a garage 5 times when the engine shut down because the DPF was blocked. Eventually one mechanic offered to drill holes through the DPF allowing the engine to breathe again and fool the pressure differential sensor into thinking that the DPF was no longer blocked. Apparently it worked a treat and they never had a problem again. Obviously on return to Europe they had to change the DPF to pass an inspection test, but they decided to worry about that when they got home – at least the fix kept them moving in South America! We have also spoken to a couple who have taken their Daily 4×4 to North Africa for several weeks and never had a problem.

Update – as of 2020 we know of several new Mercedes Sprinter owners that have travelled the length of the Americas without issues.

In light of the above experience, I am intending to take a couple of foot-long drill bits. If I have a problem with the fuel in Africa, I can simply remove the silencer and drill a few holes through the DPF until I get the engine running again (making sure I stop drilling before I get to the CAT!!). I am measuring the outputs of the differential pressure sensors with the vehicle new from the factory with a clear DPF. This is so that if I need to drill through the DPF, I can try to drill sufficient holes to restore approximately these original values. The drilling of the DPF is obviously a last resort, only if the regeneration (automatic or manually forced) does not work.

African Fuel Update

We have now completed over 25,000 km running on 500 ppm and 50 ppm diesel. We have driven a variety of roads, tracks and off road and have noticed that our average fuel economy has dropped from 14 L/ 100 km (20 mpg) in Europe to about 15 L/ 100 km (18 mpg) in Africa. Part of this reduction is probably due to the slower driving conditions in Africa, compared to Europe where long distances were done with the cruise control on motorways.

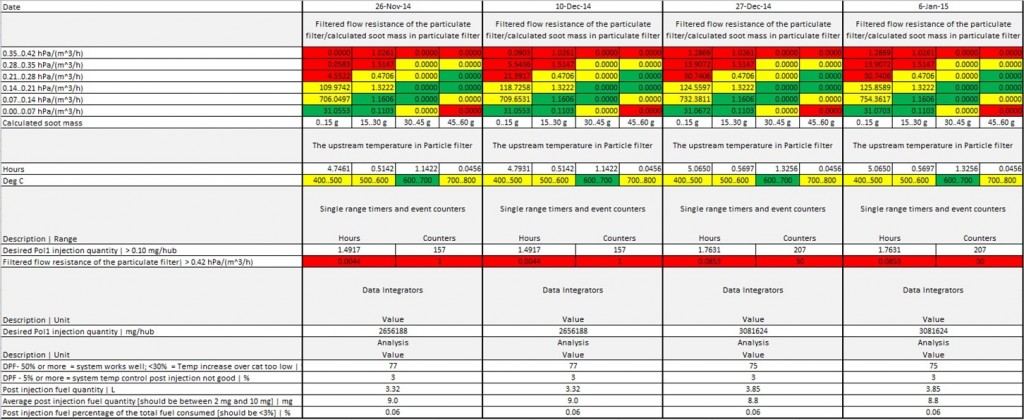

I have upgraded the software on my fault code reader and can now download the engine ‘whole-life’ history from the ECU. This has allowed me to do a more detailed analysis of the DPF performance and the quality (sulphur ppm) of the fuel being supplied in Africa. From my research it would appear that the ECU estimates how much soot should have accumulated in the DPF during engine use (due to driving style, engine load and conditions). The ECU then checks this against the actual flow resistance through the DPF. The table below is some of the actual data from Cuthbert’s ECU.

You can see from the table above that the ECU estimates the soot mass in one of four bands: 0g to 15g, 15g to 30g, 30g to 45g and 45g to 60g. (Note: Given the way we drive Cuthbert, i.e. slowly and with high loads and very few short start-stop journeys, the ECU has yet to make any calculation in the 30g to 45g band, or the 45g to 60g band!)

The ECU then calculates the actual flow resistance through the DPF. This is not a simple pressure measurement using the pressure differential sensor as the actual gas flow also needs to be calculated and this will be dependent on RPM, Turbo Boost, inlet/exhaust gas temperature and quantity of fuel injected etc. The ECU then decides which of the 6 flow resistance bands (hPa/(m^3/h)) the DPF is in and records (in relevant ‘box’ in the table against the estimated soot mass) the amount of time that it was in that band.

Most of the time the ECU estimated soot mass against actual flow resistance should be in the green boxes. However, you can see that in Cuthbert’s case the figures are higher in the yellow boxes. This is because Cuthbert’s ECU is doing its calculations assuming European diesel which has less than 15ppm sulphur. With the higher sulphur fuel in Africa the DPF is filling quicker and so the flow resistance is higher than estimated, so most of the time is spent in the higher yellow boxes.

However, this has been catered for in the software and the ECU controls the exhaust temperature to burn off the soot when required. During normal use, the soot is often burnt off through normal use: the exhaust gets hot enough to burn-out the soot without the ECU intervening. However, if the ECU then decides that this is not happening naturally enough, it can initiate a post injection to raise the DPF temperature and burn-off the excess soot.

The above process can be seen in action in the table above. Between the 26th Nov and 10th Dec Cuthbert was refuelled with diesel in Uganda. Using the data in the table above I now know that this fuel had a very high sulphur content! The table shows that by 10 Dec, the 0 to 15g band ‘recorded times’ had started to increase in the higher boxes, even going into the red on the table. By 27th Dec they were very high. It also shows that the ‘Filtered flow resistance of the particulate filter| > 0.42 hPa/(m^3/h)’ occurrences had also increased from 1 to 30, showing a very full DPF! However, between 10th and 27th Dec, the number of ‘Desired PoI1 injection quantity | > 0.10 mg/hub’ had increased from 157 to 207. The ECU had initiated 50 post injections to clear the DPF. This can be seen to have worked as the ‘upstream temperature in Particle filter‘ time had also increased.

This post injection reduced the DPF soot quantity back to normal (for Africa) limits as can be seen in the 6th Jan data. Unfortunately, I have no way of knowing exactly how high the sulphur content was in that one refuelling in Uganda. There were no indications of any problem from Cuthbert, he just kept working well as normal; only the analysis as explained above, showed that I had high-sulphur fuel. There is no reliable way of telling at the pump whether fuel has a high sulphur content, but the post- analysis helps me identify where I have picked up some bad fuel and helps me make an informed decision on where to make my next fuel stop!

Conclusion: Iveco and Bosch have done a great job in producing a Euro 5 EEV engine that can handle fuel with the high sulphur content found in much of Africa. Diesel up to 500ppm is a ‘non-event’ and fuel with a higher ppm can be handled on an occasional basis. We will hopefully be in South America later this year, let’s hope Cuthbert keeps working well on their fuel too!

High Sulphur fuel update – Jan 2016

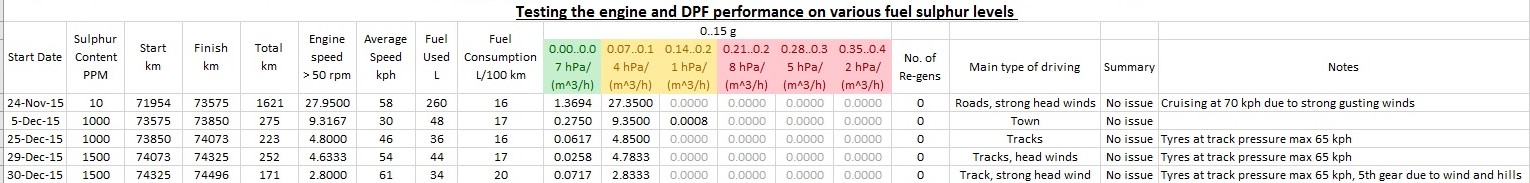

Here in South America, we are finding the sulphur content in the high sulphur fuel (diesel) to be higher than the countries we visited in Africa. We know that 500 ppm diesel is not an issue, but we need to expand the envelope if possible to cover the more common higher sulphur fuel available here. In Argentina they have 3 grades of diesel: G1 = 1500 ppm, G2 = 500 ppm and G3 = 10 ppm. In Buenos Aires we could get 10 ppm fuel, but we knew that outside of the main towns this grade of fuel would be hard to find.

Once we had used up the 10 ppm diesel from Buenos Aires, I half-filled the main tank with 500 ppm diesel (which we know does not cause any issues) and filled our second fuel tank with 1500 ppm diesel (which is available everywhere in Argentina). Then I filled the main tank with some of the fuel from the second tank, creating a mixture in the main tank of around 1000 ppm diesel. Once we had used up this fuel, I transferred more from the second tank to the main tank, making the main tank mixture around 1500 ppm.

While we were running on these mixtures I did regular downloads of the ECU stored data to obtain information on the effect the higher sulphur fuel was having on the engine and DPF. The results of this testing can be seen in the table below. Basically, there were no adverse effects of running on 1000 or 1500 ppm diesel and no DPF regenerations were required. We can now happily fill up with any grade of fuel in Argentina and we now know that Cuthbert is happy with up to 1500 ppm diesel. Once we get to the northern end of South America, some of the countries will almost certainly have fuel of up to 5000 ppm, so we will then need to carry out more testing.

So far in South America we have noticed a lower than normal fuel economy with the higher sulphur fuel. This could be caused by the driving conditions (extremely strong head winds and rough tracks) rather than the fuel quality, but it could also be due to a lower Cetane value in the fuel. Our average fuel economy figures to date by area are:- Europe 14.4 L/100 km; Africa 15.3 L/100 km; and South America 16.3 L/100 km. The overall average to date is 15.2 L/100 km (18.6 mpg, 6.6 km/L).

I have been asked questions about the performance on the (so called) ‘poor quality’ fuel sold in Bolivia. Downloading and analysing data from an ECU is obviously far more accurate than the often heard “it didn’t seem to run so well” and other unquantifiable reports, so I hope this factual approach is helpful to other overlanders.

I downloaded the ECU data prior to introducing any Bolivian fuel to an almost empty tank, so as to set a ‘pre Bolivian fuel’ baseline. I then took diesel from a YPFB fuel station in Santa Cruz and drove over 500 Km on this fuel. Intermittently over this distance I did a few more ECU downloads to monitor the engine’s use of the Bolivian fuel.

Prior to filling with Bolivian fuel, the DPF contained 12.65 g of soot. Here are the soot levels against distance travelled on Bolivian fuel:-

Soot Level Total distance travelled

12.65 g 0 km

0.85 g 213 km

1.25 g 324 km

0.55 g 505 km

These fluctuations are quite normal (could even be described as a ‘low‘ levels of soot generation; the maximum amount the DPF can hold before blocking is 60 g) and indicate that the fuel does not have a very high sulphur, oil or other contaminate content. The ECU did not initiate any post injections to raise the exhaust temperature to help the DPF regenerate and the exhaust stayed below 400C the whole time. The measured flow resistance through the DPF against time (hours) was:-

Flow resistance in the DPF Time in Hours

0.35 to 0.42 hPa/(m³/h) 0 0 0 0

0.28 to 0.35 hPa/(m³/h) 0 0 0 0

0.21 to 0.28 hPa/(m³/h) 0 0 0 0

0.14 to 0.21 hPa/(m³/h) 2.1125 0 0 0

0.07 to 0.14 hPa/(m³/h) 9.1167 0 0 0

0.00 to 0.07 hPa/(m³/h) 0.0956 0 0 0

Calculated soot mass 0 to 15 g 15 to 30 g 30 to 45 g 45 to 60 g

These figures also confirm that the fuel did not have a very high sulphur, oil or other contaminate content. The ECU also calculated that the fuel consumption averaged 13.99 L/100 km, which was 1.46 L/100 km better than the performance the engine had been averaging with Chilean fuel. Obviously there are several factors which affect fuel consumption, but this slight improvement in performance does at least indicate that the Bolivian fuel has an equivalent, or possibly slightly higher, Cetane number than the average fuel I had previously been using from Chile.

Conclusion: the fuel in Bolivia from the YPFB station was of a comparable quality to that found in Chile and is not ‘poor quality’! Obviously this is only a single fill up from one station and I have not tried any other brands available in Bolivia. However, my assumption is that the fuel stations in the YPFB network all receive a similar quality of fuel, so YPFB would probably be a good choice for fuel in Bolivia if you are concerned about quality. As the fuel has a reasonable Cetane number, I would also advise against the use of any additives, especially if your vehicle has a DPF.

We are heading into Brazil now but will be back in Bolivia in a few weeks where I will get more fuel and do some more testing.

Update – 19 Jul 2016

We re-entered Bolivia from Brazil and headed west. After filling up with fuel from a YPFB station in Sucre, we took more fuel from local (‘no-name’, non-YPFB) petrol stations in Potosi and Tupiza before heading into the remote mountains for the South Laguna route. Of our 3 fuel tanks: the rear was empty, the second tank had YPFB fuel from Sucre and the main tank had a mixture of the fuel from the two non-YPFB stations. Our two jerry cans also had non-YPFB fuel.

We left Tupiza using the main tank (non-YPFB) fuel and noticed a sharp increase in fuel consumption. Normally through high mountains I would expect the fuel consumption to increase from an average of 16 L/100km to about 18 or 19 L/100km but here we were getting around 23 L/100km. This was an initial indication that the non-YPFB fuel was not good. That evening I topped up the main tank from the two jerry cans (again non-YPFB) and noticed that the gauze filter in the jerry can spout had some wax deposits, not a good sign at +4C! I also down-loaded the ECU data and found that the DPF was filling very quickly, it was at 18.53 g.

The following morning at 4200 m it was -18C; the two fuel filters were blocked with waxed fuel and the engine pre-heater was also blocked. Luckily I was able to turn on the heaters in the two fuel filters, this melted the wax and enabled me to start and run the engine (see full story here). I can highly recommend heated fuel filters, especially if you use fuel that is likely to wax – it is a much better option than adding additives.

That evening after a day of driving, I did another ECU download – the DPF had filled to 28.09 g, an increase of 9.56 g over only 117km! This clearly showed the non-YPFB fuel to have a high sulphur content or other contamination. The following day I tried to drive with the engine at about 3000 rpm for about 20 minutes. This is supposed to help burn-out the DPF, however that evening I checked the ECU data again and the DPF soot had now increased to 36.89 g. At this rate the DPF would be blocked (60 g) within the next 3 days!

I tried to force a regeneration of the DPF but not surprisingly at 4100 m it was unsuccessful and actually increased the DPF soot to 39 g. We decided to drain all the (non-YPFB) fuel from the main tank and transfer it to the empty rear tank. I then transferred the YPFB fuel from the second tank to the main tank.

The next day we headed towards the Ollague border to Chile (at north end of the Laguna route) so that we could try another forced regeneration of the DPF at slightly lower altitude. If this forced regeneration did not work at 3700 m, we then had the back-up option of crossing into Chile and descending to a much lower altitude. The forced regeneration did not work again due to the altitude, however we noticed that over the short drive towards the border (around 40km), the soot had decreased slightly to 38.62 g. This reduction in the soot through normal driving with YPFB fuel was encouraging and showed how much better the YPFB fuel is.

Rather than descending in Chile, we decided to try driving to Uyuni along route 701 (a dirt road but reasonably smooth) at the optimum speed to try to self-regenerate the DPF using the YPFB fuel. I set up the diagnostic computer to monitor the exhaust temperature and DPF soot levels etc so that Julie could monitor them during the drive. We found that a cruise at 80 kph was optimum.

At faster speeds the increased soot produced by the engine at the higher power counteracted the burning-off of the soot. At lower speeds, the exhaust was not hot enough to burn off the soot. But at 80 kph with the cruise control set, and despite the route being at around 3700 m, it burned-off the soot nicely. By the time we arrived in Uyuni, the soot had reduced to just 13.1 g: a reduction of 25.52 g over 220 km. Very happy.

Needless to say I will only be buying fuel from YPFB in Bolivia and avoiding all other petrol stations. Click here to find out how we got the fuel in Bolivia.

You may find my page on High Altitude Operations interesting too.

Update 27 Jan 2019

We have now been in Mexico for three months, the land of low sulphur diesel. All Pemex diesel is now ultra low sulphur. We have had no issues with fuel through the remainder of South America or Central America. We bought diesel in every country in South and Central America except for: Venezuela which we didn’t visit at all, and Nicaragua which we drove through in a day and had no need to buy diesel there (click here to see why).

We have been contacted by several people with newer vehicles requiring Diesel Engine Fluid (DEF) also know as AdBlue in Europe, Arla32 in Spanish speaking American countries and Urea32 in Brazil. Although we don’t use this fluid, we have seen it throughout the Americas. It isn’t generally available at fuel stations but is often sold in the truck-shops selling lorry oils, often in 20L containers. If you are headed that way, try Googling Arla32 or Urea32 to find suppliers.

Another IMPORTANT point I would like to add is the effect of engine oils on the DPF. We have met a few vehicle owners that had never heard of low SAPS oils. Low SAPS oils contain reduced quantities of Sulphated Ash, Phosphorus and Sulphur. If you use a normal engine oil it will lead to your DPF blocking extremely quickly, probably faster than it would block if you were operating with high sulphur fuel! I believe that some of the issues people have experienced with a blocked DPF could have been the result of incorrect oil use. If you take your vehicle for a service in a country that does not normally have vehicles with DPFs, there is a strong possibility that they will use a normal and not low SAPS oil. This seems to be the case even with main-dealers for the vehicle type; if the Mercedes dealer is not familiar with DPFs in their country, they may not be aware of the importance of low SAPS oils. I was surprised when I looked at the oils in a Mexican Autozone shop; out of the 5 or more 5W30 oils on the shelf, only one of them was low SAPS. If the oil isn’t labelled as low SAPS, check for an ‘ACEA grade C’ oil to confirm that it is low SAPS.

Hey… was this useful? If so, you might like to support our website costs with a donation below. Thanks 😊👍