While driving on rough tracks in Kenya, a very small water leak developed on the engine radiator. It only leaked during strong vibrations; on normal roads it was fine. I looked in the workshop manual to see what was involved in replacing the radiator. The manual explained that for this task I would need to:

· remove the front of the truck (incl. winch, bumper, headlights and grill)

· drain and remove the power steering cooling loop

· drain and disconnect the air-conditioning system

· disconnect the intercooler

· remove the radiator, intercooler and air-conditioning radiator assembly

· then finally… remove the radiator from this assembly once it is out of the truck!

This was obviously going to be a big job with lots of potential for complications! Cuthbert was booked in for a service at the Iveco garage in Arusha, Tanzania the following month so I thought I might have them do the job under warranty. However, when we got to Arusha, the Iveco garage was very shabby. They had no parts (I had to supply all the consumables and oils for the service) and none of the specialist Iveco tools or even the Iveco diagnostic computer to re-set the oil counter post service. This was not the place to have the radiator replaced! The quick fix was to use a bottle of Radweld and the leak was fixed for the time being.

Over a year later we found ourselves in Iquique, Chile and the air-conditioning radiator had developed a small leak. By this time we were out of the warranty period, so I decided to do the work myself. I also decided that whilst fixing this leak, I would take the opportunity to replace the radiator which had recently started to show a tiny leak again, for the first time since Kenya. The local Iveco garage in Iquique had a spare radiator in stock but had a 6 week lead-time for an air-conditioning radiator (and it was a crazy price). So finally I decided to replace the radiator and have the air-conditioning radiator repaired locally.

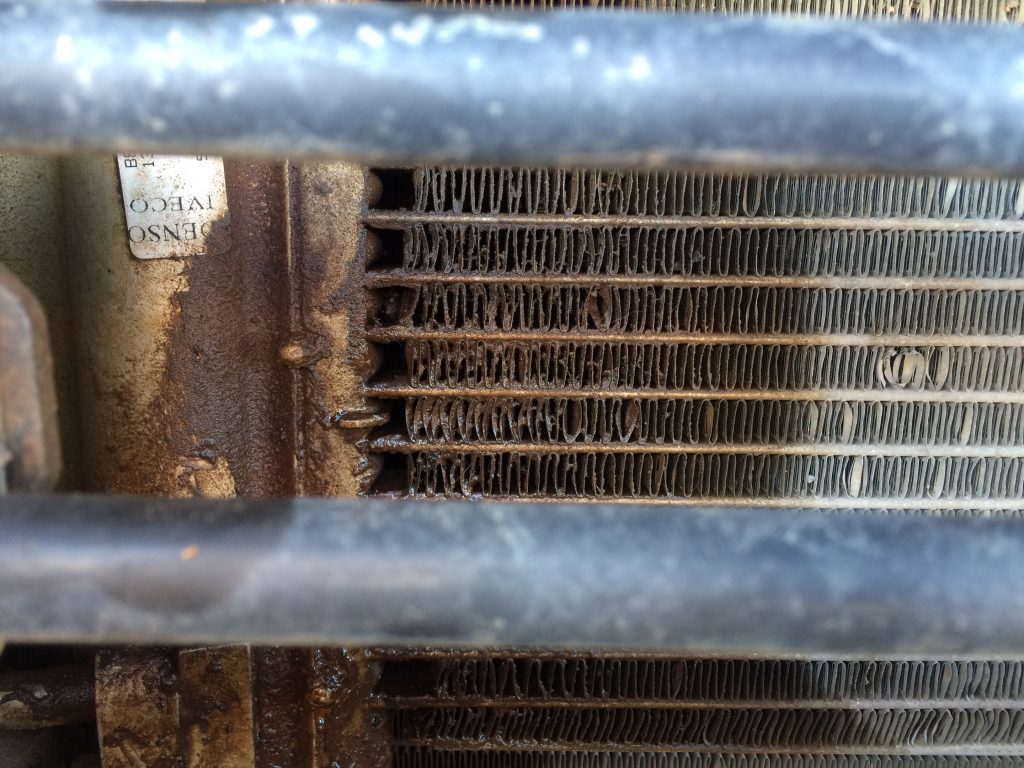

The leaking AC radiator

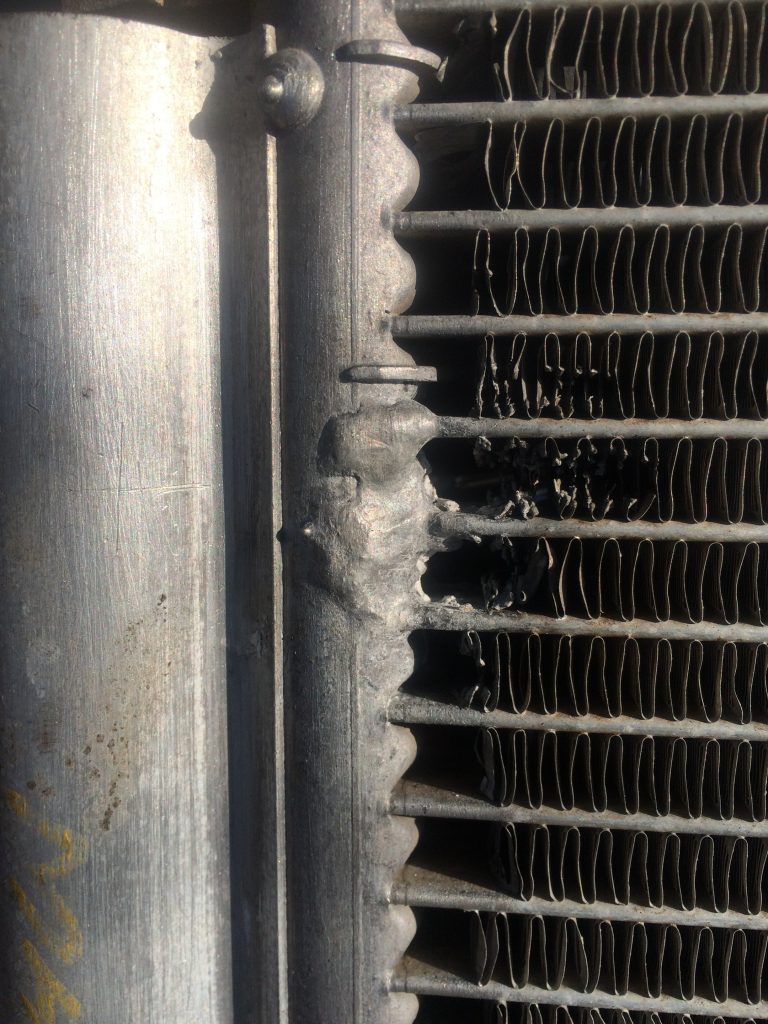

The AC radiator leak

Setting about the job, I wanted to see if the radiator could be replaced without all the draining and stripping of the adjacent systems as listed in the manual (see above). Removing the front of the truck was quite an easy process taking less than an hour, including the complication of removing the winch. With the front removed, there is great access to the engine. I flushed the cooling system through with a cleaning product (I had added it the day before so it could start working whilst we were driving). I then found that I could extract the radiator without draining or disconnecting the other systems. So much for the workshop manual and its overly complicated procedure!

Front of the truck removed

Radiator removed with the other systems still connected

Once the radiator was removed I could see that the rubber block on the mounting bracket for the radiator was starting to wear. There were no spares available from the local Iveco garage, but I managed to make a temporary repair which should last a few months.

Radiator mounting rubber starting to fail

Temporary repair to mounting rubber

Crack in the air filter bracket

I also noticed that the bracket for the air filter had a fatigue crack, so I removed this and had both this and the air-conditioning radiator repaired in a local workshop. With these fixed, I reassembled the truck.

The repaired AC radiator

Finally, all I needed was to have the air-conditioning recharged. The Iveco garage recommended a local specialist air-conditioning engineer who when we called him, kindly offered to pop over to the campsite and refill the system for us at the site! What a service! All in all, it was not a difficult job. The AC is back to full strength ready for any hot weather ahead and the timing worked out well as the coolant fluid was due for changing as part of the T4 (3 yearly) service.