The brakes system uses rubber hoses to connect various sections of the pipe work together. As the cab is not fixed solidly to the chassis, hoses are needed between the master cylinder and ABS, between the chassis and axles, and between the front axle and front brake callipers. This all totals up to an incredible 3.9 m of hoses! The problem with hoses is that they expand a little every time the brakes are applied. This gives longer brake pedal travel and a slightly spongy feel to the brakes. Many years ago, when I used to tune Minis, I always used Goodridge brake hoses in place of rubber hoses. The Goodridge hoses have a PTFE inner pipe, covered in a stainless steel over-braid. I ordered pipes with a black outer cover, so they look more like the original and there is no stainless-steel showing. This allows the pipe to flex, but it doesn’t expand under pressure. I ordered a set, made to measure for Cuthbert, from Merlin Motorsport at Castle Combe Circuit UK www.merlinmotorsport.co.uk . I had great support from Merlin Motorsport and can highly recommend them. Thanks, Gary for all your help.

New Goodridge Brake Hoses

The ABS master cylinder inputs are M12, but unfortunately I ordered M10. The original M12 pipe fittings have the same size nut as M10 fittings, which is why I missed it during planning. To fix this, I had to fit a couple of M10-to-M12 brake adaptors; then the new hoses fitted.

- New master cylinder to ABS hoses

- M10 to M12 brake pipe adaptors

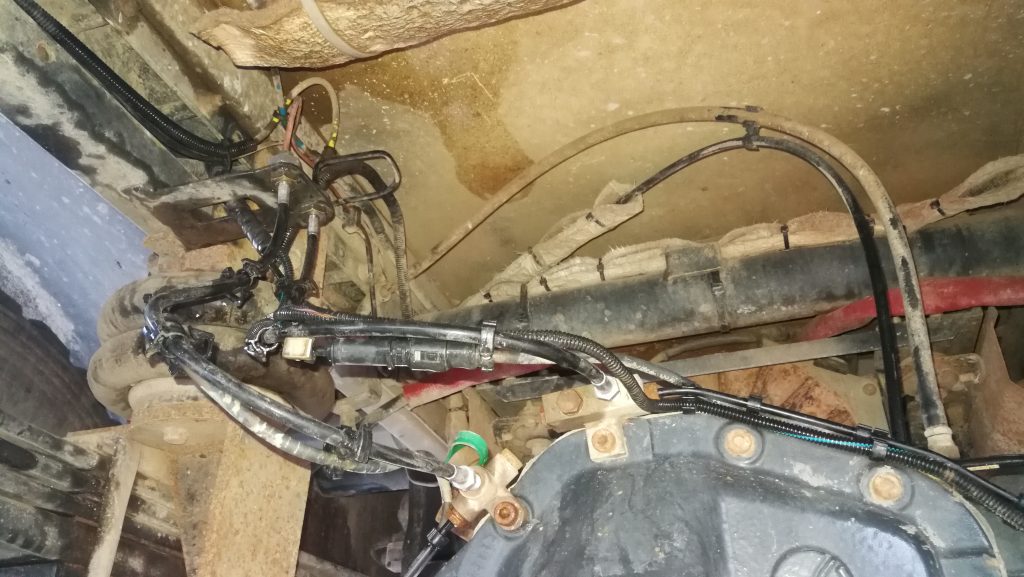

- The M10 to M12 brake pipe adaptors fitted to the ABS unit

When fitting the rear hoses, one of the steel pipes broke when I undid it. I have heard that a few people have had this pipe break. I removed that section of pipe and replaced it with a copper pipe that I made up. This lasted until I was able to get a new section of pre-terminated steel pipe from a local car store a few days later.

New rear brake hoses installed. The copper pipe was only used temporarily until I could get a new steel section.

The front hoses were quick and easy to swap out, I just reached in above the wheel.

New front hose installed.

I would highly recommend an 11mm crows foot spanner for doing the pipes fittings.

An 11 mm crows foot spanner is very good for the hose and pipe fittings

After bleeding the system, I went for a test drive: the brake pedal is much firmer, the spongy feeling is gone. I tried the ABS on gravel and it felt sharper. I couldn’t say if it’s more effective or not, but I suspect that it is improved as the pump doesn’t have to inflate the pipes. With the original pipes I had 40mm of pedal movement, with the new pipes it’s down to 10mm (this is after the initial mechanical slack for the pedal to engage the master cylinder piston).

The pipe set that I ordered from Merlin Motorsport is as follows (note this is for LHD, if your vehicle is RHD your master cylinder to ABS hoses will be different):-

Master cylinder to ABS

2x 90 deg M10 swivel male to straight M10 (should be M12) male dual seat swivel stainless, length 540 mm (end of fitting to end of fitting).

Chassis to axles

4x Goodridge female bulkhead metric concave to Goodridge swaged M10 x 1 bulkhead (doesn’t need to be bulkhead on male end), length 540 mm (end of fitting to end of fitting).

Front axle to calliper

2x Goodridge female bulkhead metric concave to Goodridge swaged 20 degree extended neck banjo, length 380 mm (end of fitting to end of fitting).

Nuts for female bulkhead fittings

6 x Goodridge 5/8″ whitworth steel half nut

Bolts and washers for banjo fittings

2 x Goodridge banjo bolt single M10 x 1 (20 mm long)

4 x Goodridge copper washer 3/8″ unf, -3 jic & M10

Miscellaneous

16 x Goodridge -3 tuv swage brass collar

8 x Goodridge hose swage – charge for making each hose

Total cost in Oct 2018 £270 inc VAT