Problem: Often when driving uphill or accelerating hard, we got the dreaded ‘beep’ and a “Check Engine 024” warning on the instrument cluster. The EDC warning light came on, the engine reduced power and entered ‘limp mode’ (i.e. reduced power but still fully drivable). Time for some diagnosis work.

The diagnostic computer revealed two error codes:-

DTC 1118 OBD P0299, Boost Air Pressure Check; Injection correction factor lower than the expected one

DTC 2118 OBD P0234, Boost Air Pressure Check; Injection correction factor higher than the expected one

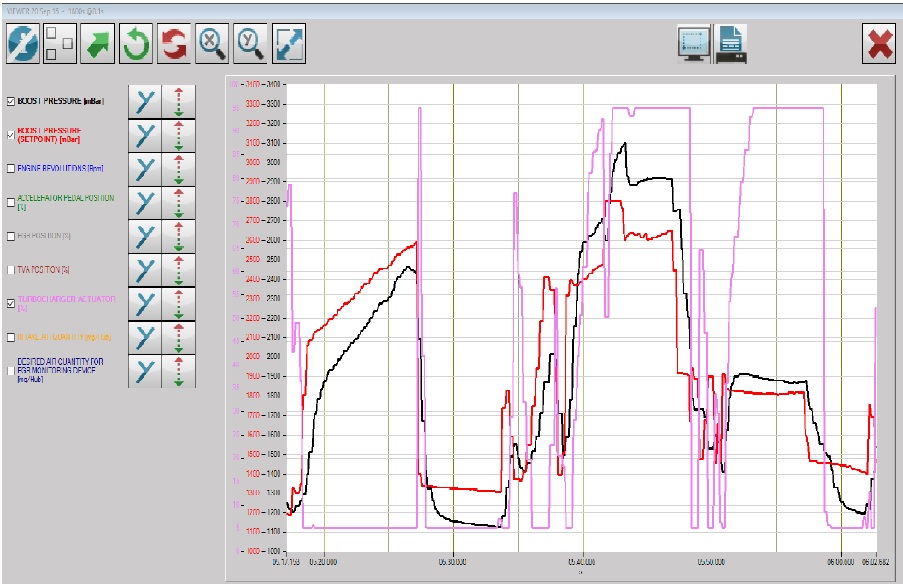

First action was to check the boost air (turbo output). We did a short drive while recording some engine parameters and the results revealed that the boost air pressure was occasionally exceeding the ECU’s requirements (this is despite the ECU trying to reduce the turbos’ output). The graph below shows the ECU’s desired boost pressure in red, the actual boost pressure in black and the turbos’ actuator control in purple. It shows that at one point, the actual boost pressure exceeds the ECU’s requirements, even when the ECU is driving the turbos’ actuator to over 90%; this event set off the “Check Engine 024” warning and put the engine into ‘limp mode’ for protection.

Boost Pressure Graph

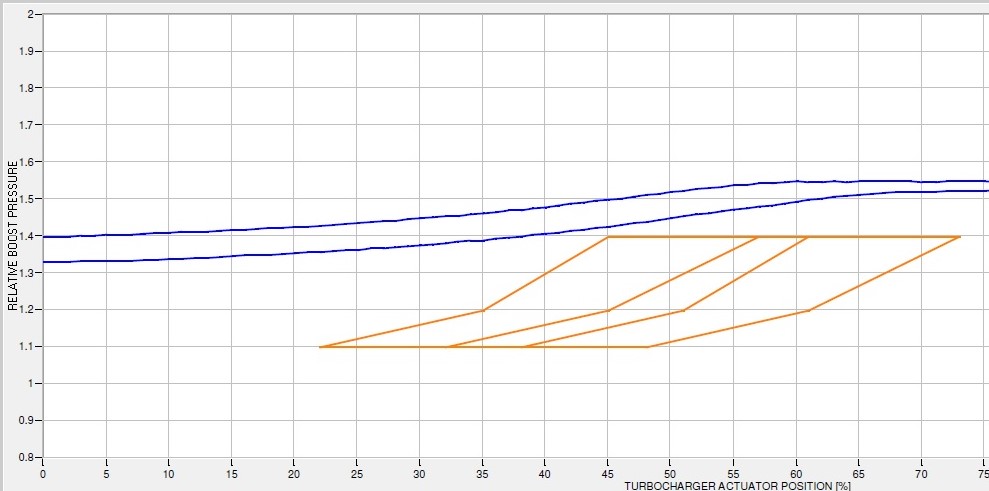

Next, time to test the turbo. This is quite easy: plug in the laptop and tell it to do a turbo test! The computer runs the engine up to 3000 rpm and operates the turbo actuator from 0% to 100% then back to 0%, whilst recording the ratio of the boost pressure to atmospheric pressure. The results did not look good. The graph below shows that there was some boost pressure continuously present, and that the increase and decrease cycles completely missed the gates that they should have passed through!

Failed Turbo Test!

It quickly became clear that the actuator was jammed and didn’t move in response to ECU commands. It was a fiddly, but relatively easy job to remove the actuator. The end of the actuator rod that connects to the turbos bypass valve (see photo below) had seized together.

Turbo Actuator Linkage

Once I had managed to separate the actuator rod-end from the turbo bypass valve arm, I cleaned up the parts and slightly enlarged the hole where the two parts join.

Turbo Actuator Rod-end

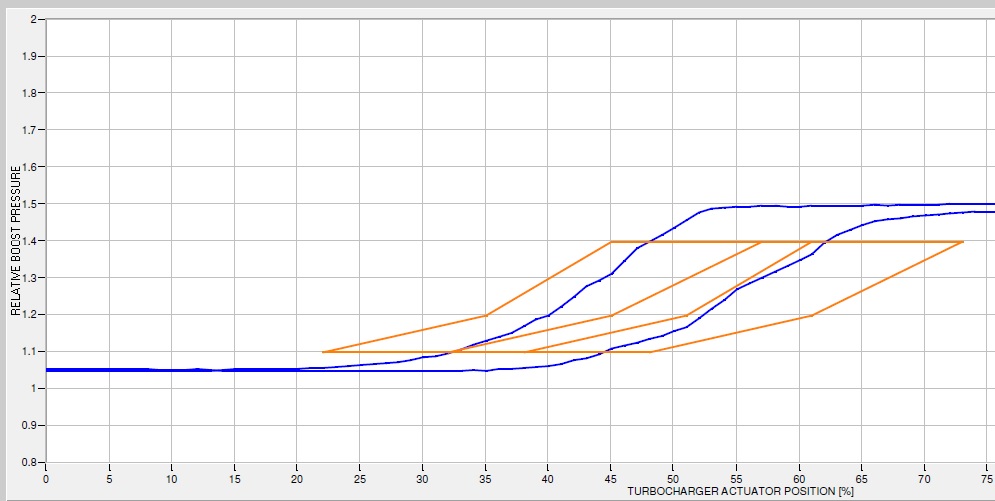

After reassembling, I carried out another turbo test. The graph below shows the boost pressure now increases and decreases correctly through the gates. The ECU has control of the turbo once again.

Successful Turbo Test

So in conclusion, does this problem prove that old trucks without modern electronics, make better overlanding vehicles than modern geeky trucks? Some argue that the kind of problem we had above, is strong evidence to support the case against modern electronics in overlanding trucks.

In response I would argue that had this been an old truck and the waste gate had seized-up as it did here, we would not have had any indication of the problem and would have continued to drive until the head gasket blew (or worse). We would then have been stuck at the side of the road with a useless engine and a world of hassle pending.

Instead, Cuthbert’s geeky modern engine detected the snag, warned us of the problem and protected the engine by putting itself into limp mode (reduced power). We could continue driving and had no pending engine rebuild! By plugging the computer into the engine whilst driving, I was able to record and store the engine performance data, then analyse it at the end of the day (it’s not necessary to watch the computer whilst driving). Had I wanted to collect that kind of data for analysis for an old truck, it would have required a very complex and expensive exercise on a rolling road and even then, most of the data would not be available! I don’t want to go back to the dark ages 😉