We’ve heard bad things about Euro diesel engines at high altitude. Now we’ve been crossing the Andes between Chile and Argentina a few times, I thought it would be a good opportunity to have a look at how Cuthbert, with his Euro 5 diesel engine, performs at high altitude (in excess of 3800 m, 12,500’). Cuthbert was loaded to between 5900 and 5750 kg (13,007 and 12,676 lbs) for the crossing.

Engine Cooling

Generally, for Euro diesel engines at high altitude, the engine cooling is not as efficient as it is at sea-level; the air density is lower (at 5500 m, 18,000’ air density has reduced to half that of sea level) so the radiator becomes less efficient. However, I also noticed that Cuthbert’s cooling is very sensitive to tail winds.

On a long mountain track climb with multiple switch-backs, I noticed that driving in one direction the temperature gauge indicated up to three quarters, but driving in the other direction it rapidly dropped back to just above half. In both directions we were in the same gear, maintaining approximately 35 kph, the GPS vertical speed was showing the same rate of climb (i.e. the gradient of climb was approximately the same in both directions) and the cooling fan remained on throughout. I then realised that in the ‘cooler’ direction, we were heading into wind, whilst in the other direction we had a tail wind.

The wind was not very strong (less than 20 kph) so it was quite surprising to see such a large variation in engine temperature. I also noted from our Engine Watchdog temperature monitor, that we had a very high indicated main gearbox temperature of 108 C and transfer gearbox of 98 C (normally neither of these go above about 85 C). The temperature sensors for the Engine Watchdog are bolted to the outside of the gearboxes and the hot air from the engine cooling system was blowing over them. This effect was confirmed by stopping and turning into wind, upon which the temperatures dropped very rapidly; far faster than it would normally take a gearbox to cool down.

Another time, whilst driving on a rough track up the side of a mountain, cutting a fresh track through a section of snow about 20-30 cm thick at just over 4,400 m (14,400’) altitude, the ‘engine overheat’ warning illuminated on the dashboard, with an instruction to shut down the engine! I stopped and reversed through 90 degrees to point into the prevailing wind (it had been a slight tail wind). I also put on the cabin heater and opened the windows, but kept the engine idling. Almost instantly the temperature gauge reduced to three quarters and within a minute the engine temperature gauge reduced to indicate half!

I am not a great believer in switching off an overheating engine as it can lead to a lot of damage with the hot water not circulating and so possibly warping the cylinder head. It is far better to keep the engine idling to allow the cooling system to keep the water circulating. It is worth noting that above 102 C, the engine ECU starts reducing the maximum engine power so that the engine power is reduced to 50% by 112 C; but I had not noticed any reduction in power.

That evening I downloaded the ECU data and could see that the engine cooling system had been in the range of 106 C to 113 C for 4 minutes and 5 seconds. The ECU records temperatures in the five range-bands of: 99-106 C, 106-113 C, 113-120 C and 120-127 C and any events in excess of 127 C. This warning was only in the second of these five bands, so I am not worried about this slightly high temperature event.

As we were parked up for a couple of days, I decided to see if I could improve the radiator’s cooling performance. The radiator inside the truck is large in comparison to the front grill, so the obvious improvement would be to make the grill bigger to allow more cooling air to the radiator. Given the design of the front bumper and the supporting structure, I decide to drill some additional holes in the bumper to increase the air flow to the radiator. I used the same hole spacing as the existing grill but cut 24 round holes 19 mm diameter, instead of the square 20 mm x 20 mm ones used in the Iveco design. I chose multiple small holes (rather than fewer larger holes) for the following reasons:

- Maintain radiator protection in the event of a strike by a bird or other animal (don’t want any big bits hitting and damaging the radiator)

- In very cold weather when less cool air is required, it will be easy to cover the holes with duct tape

I have calculated that these additional holes have increased the airflow to the radiator by approximately 9.8%. To check the performance of the new holes we climbed a track with a very similar gradient to the one mentioned above (matching the speed and rate of climb so that the test results would be comparable to the climb that we did before the holes were cut). I noticed that the temperature gauge rose to just above half, but sat below the threshold for the fan to switch on. Previously in these conditions, we would have had the fan on and the temperature gauge up to three quarters! So far this seems to be a great improvement and was easy to implement. The new holes can be seen in the photo below (the yellow is paint primer and will have a top coat of black paint when I can find some).

General Driving

Other than the engine temperature sitting a little higher at altitude while climbing hills, the only other noticeable change for Euro diesel engines at high altitude, is a lack of engine power until the turbos spin up. The engine starts and idles normally, but if I try to pull away normally there is very little engine power. However, if I rev the engine gently to about 2000 rpm over about 3 seconds, release the throttle to allow the engine to return to idle and then pull away normally, I have normal power.

This procedure spins up the two turbos which then boost the air pressure to allow normal performance. I also ensured that the engine temperature is back to half (or less) on the temperature gauge before switching off the engine. When at altitude I also leave the engine idling a little longer before switching it off to allow the turbos a little more time to spin down in the thin air.

Engine Pre-Heater

We have the Iveco-installed Webasto engine pre-heater that uses a diesel burner to pre-heat the engine and cab. I have found that this works ok at altitudes of 3800 m, 12,500’. I have also noted (from ECU data) that when this pre-heater is used to warm the engine prior to starting, the engine does not use the glow plugs during the start cycle (worth remembering should we ever have a glow plug issue).

Fuel

I filled up with standard Chilean diesel 15 ppm (not the Euro Diesel) for our last Andes crossing. Cuthbert’s fuel system consists of two fuel filters. The first fuel filter is between the fuel tank and electric fuel pump and is primarily for water separation and course filtering. The second fuel filter is between the electric fuel pump and the common rail high pressure fuel pump, this is a very fine filter. Both of these filters have heaters controlled by the ECU for when the fuel is cold. During the crossing the lowest temperatures I encountered were only -3 C, quite warm for the altitude. I did not experience any starting, running or waxing issues with this fuel and the ECU did not use the fuel filter heaters.

DPF

I have read several accounts of Euro diesel engines at high altitude where people have issues with their DPF blocking and causing their vehicle to shut down. I have therefore decided to try and monitor Cuthbert’s DPF performance; here is the data I captured:

Maximum altitude = 4725 m, 15,500’

Minimum temperature = -3 C

Engine running times downloaded from ECU

- Below 1000 m, 3,300’ = 1.0214 hours

- Between 1000 m, 3,300’ and 2000 m, 6,600’ = 1.4961 hours

- Over 2000 m, 6,600’ = 12.7658 hours

- (I estimate that approximately 10 hours were over 3800 m, 12,500’)

Number of DPF regenerations = 0

Total distance travelled = 647 km

Total fuel used = 111 L

Filtered flow resistance of the particulate filter/calculated soot mass in particulate filter

- 0.35..0.42 hPa/(m³/h) 0 0 0 0

- 0.28..0.35 hPa/(m³/h) 0 0 0 0

- 0.21..0.28 hPa/(m³/h) 0 0 0 0

- 0.14..0.21 hPa/(m³/h) 0.0336 0 0 0

- 0.07..0.14 hPa/(m³/h) 15.3333 0 0 0

- 0.00..0.07 hPa/(m³/h) 0.3886 0 0 0

- Calculated soot mass 0..15 g 15..30 g 30..45 g 45..60 g

The upstream temperature in Particle filter

- Hours 0.1497 0 0 0

- Deg C 400..500 500..600 600..700 700..800

Soot in the DPF

- start of climb = 0.91 g

- mid-point of crossing = 7.08 g (maximum allowed 60 g)

- end of decent = 1.94 g

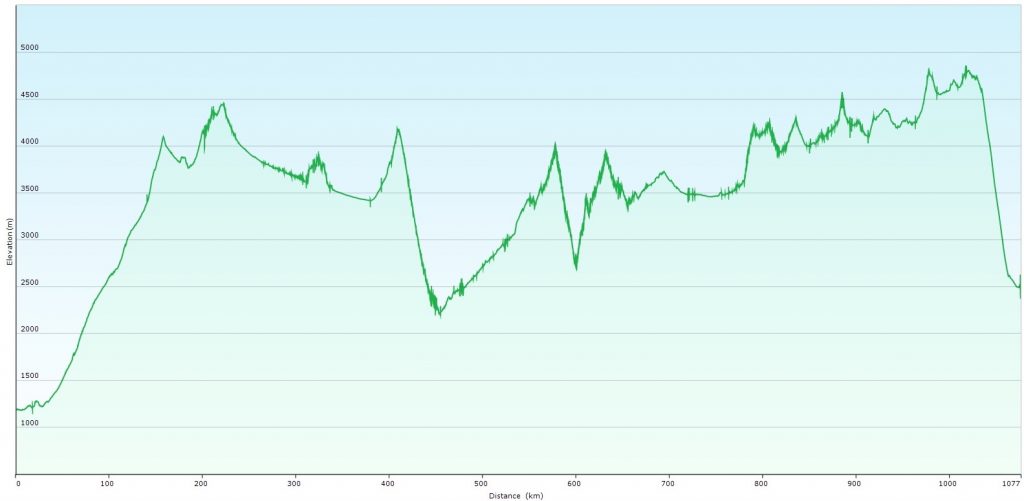

Altitude profile

So what does all this data mean for Euro diesel engines at high altitude ?

So what does all this data mean for Euro diesel engines at high altitude ?

Basically, the engine and DPF operated as normal with no significate variation due to the altitude. The DPF regenerated itself through normal driving and exhaust temperatures. No intervention was initiated by the ECU to raise the exhaust temperature to regenerate the DPF. However, in a few months’ time we will be in Bolivia and probably operating on higher sulphur fuel. This is likely to produce more issues and I will track the engine and DPFs performance then.

Update – Andes crossing: Argentina to Chile – Jama Pass

Here is a quick update for our latest crossing of the Andes, this time using higher sulphur fuel.

Maximum altitude = 4808 m, 15,774’

Minimum temperature = -4 C at 4142 m (13,590’)

Engine running times downloaded from ECU

- Below 1000 m, 3,300’ = 0 hours

- Between 1000 m, 3,300’ and 2000 m, 6,600’ = 1.8439 hours

- Over 2000 m, 6,600’ = 25.2267 hours

Number of DPF regenerations = 0

Total distance travelled = 1077 km

Total fuel used = 50 L, 1500 ppm; 100 L, 500 ppm; 47 L, 10 ppm

Filtered flow resistance of the particulate filter/calculated soot mass in particulate filter

- 0.35..0.42 hPa/(m³/h) 0 0 0 0

- 0.28..0.35 hPa/(m³/h) 0 0 0 0

- 0.21..0.28 hPa/(m³/h) 0 0 0 0

- 0.14..0.21 hPa/(m³/h) 1.4689 0 0 0

- 0.07..0.14 hPa/(m³/h) 23.5667 0 0 0

- 0.00..0.07 hPa/(m³/h) 2.0300 0 0 0

- Calculated soot mass 0..15 g 15..30 g 30..45 g 45..60 g

The upstream temperature in Particle filter

- Hours 0.3314 0 0 0

- Deg C 400..500 500..600 600..700 700..800

Soot in the DPF

- start of climb = 1.72 g (maximum allowed 60 g)

- mid-point of crossing = 11.36 g (maximum allowed 60 g)

- end of decent = 11.13 g (maximum allowed 60 g)

Altitude profile

And what does all this data mean for Euro diesel engines at high altitude ?

And what does all this data mean for Euro diesel engines at high altitude ?

As with previous high-altitude crossings of the Andes, the engine and DPF operated as normal with no significate variation due to the altitude or the higher sulphur fuel. The DPF regenerated itself through normal driving and exhaust temperatures. No intervention was initiated by the ECU to raise the exhaust temperature to regenerate the DPF.

In a couple of weeks’ time we will be in Bolivia and probably operating on higher sulphur fuel. This may produce some issues and again I will be tracking the engine and DPF’s performance.

Shortly after this crossing we ascended to 4312 m (14,150’) and camped overnight. The following morning it was – 7 C outside. The Webasto engine pre-heater worked perfectly and the engine started without issue, despite the cold and altitude.

I have been contacted by a number of people about DPF issues. One problem that people seem to be having could possibly be connected with the use of incorrect oil. Most people are familiar with the ‘normal’ grades of oil, for example the Iveco Daily 4×4 uses 5w30. I have found this grade of oil, or the higher specification 5w40, quite easily in many countries. However, with a DPF you need a Low SAPs version of oil with limited sulphate ash, phosphorous and sulphur content (SAPS); these oils are not so common. If you don’t use a Low SAPS oil, your DPF will block very quickly regardless of fuel quality. In Europe this is a common cause of DPF failure, even when operating on very low sulphur fuel! You need to look for ’ACEA Grade C’ oil, which is the Low SAPS version for engines fitted with a DPF.

Don’t forget that if you have your vehicle serviced by a dealer in a country where the local vehicles are not normally fitted with a DPF, the technicians will probably never have heard of SAPS. They are likely to use the ‘normal’ oil grade (i.e. 5w30) and not the low SAPS oil required for a DPF engine. This will lead to a very quick DPF failure.

Turbo Performance at High Altitude

I have been asked a few questions about Euro diesel engines at high altitude and particularly the turbo performance at high altitude, so I hope you find the following useful.

The turbo increases the pressure (and therefore quantity) of air entering the engine. This in turn allows more fuel to be burned and therefore gives more power. However, another advantage of the turbo is that it compensates for the reduction in air pressure at altitude. Whilst driving at altitude, I only noticed a reduction in power when trying to pull away before the turbos had ‘spun-up’ to normal operating speed. To compensate for this, I revved the engine to about 2000 rpm for a few seconds to ‘spin-up’ the turbos before trying to pull away. Once the turbos were up to normal speed, the truck felt like it had normal levels of power, but I wanted to check the engine data to see whether there was actually any power-drop that I was not noticing.

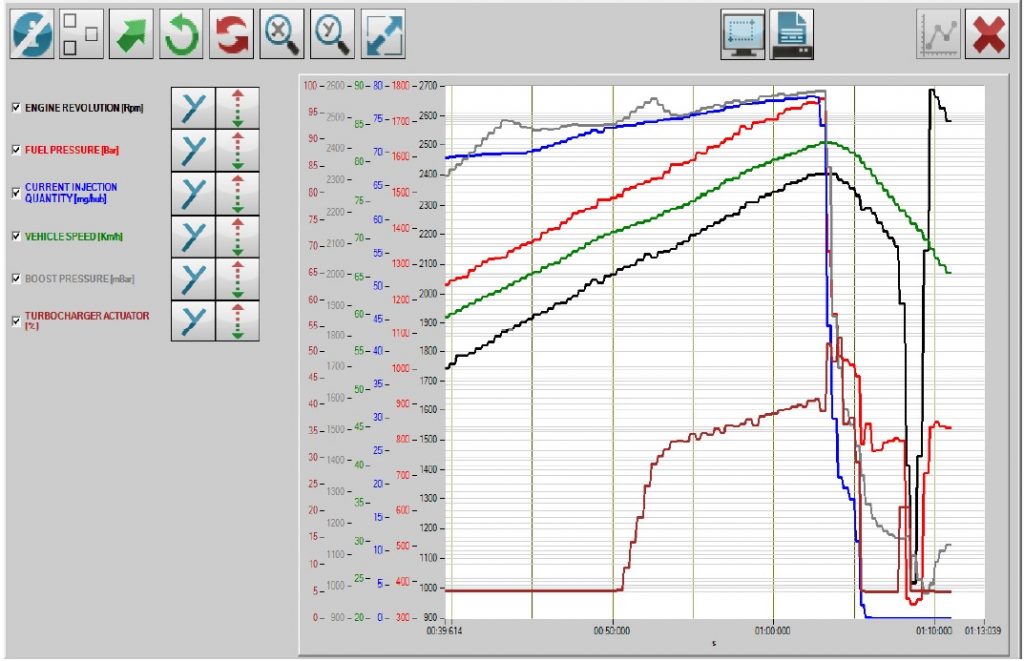

My engine diagnostic computer allows me to record any of the engine’s parameters and replay them later for analysis. At an altitude of approximately 1000 m (3,300 feet) above sea level, I accelerated at full throttle and recorded the results seen in the graph below. The maximum turbo boost pressure was 2584 mb.

Turbo performance at 1000 m (3,300 feet) maximum boost pressure 2584 mb

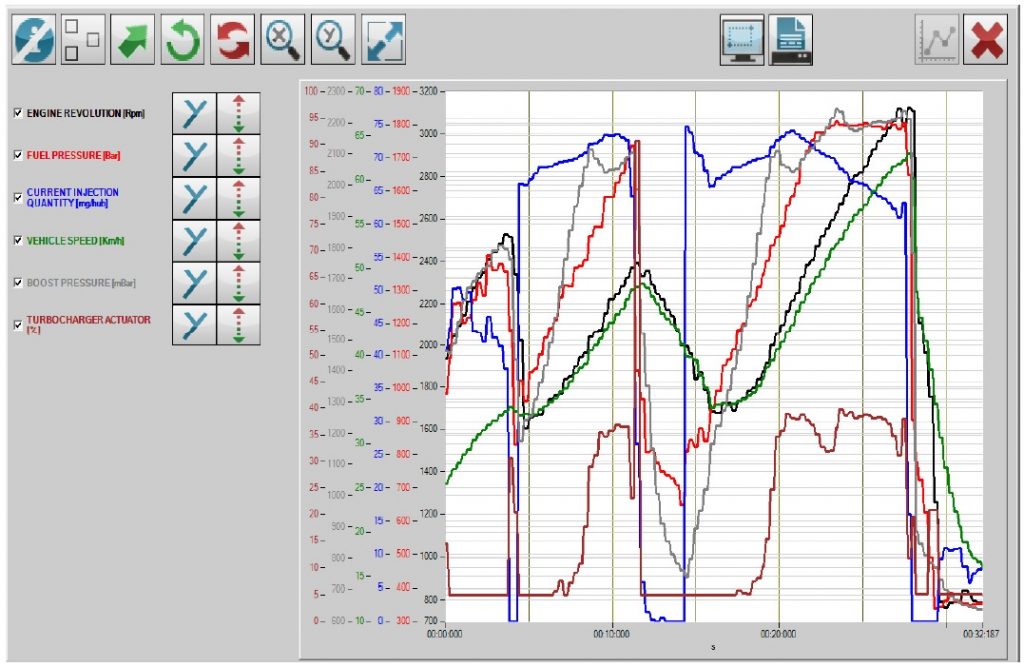

Then at around 4,200 m (13,800 feet) I performed another acceleration at full throttle and captured the data in the graph below. Unfortunately, this time I was on a dirt track with lower tyre pressures, so I could not replicate the first test identically with regards to gear selection and vehicle speed, but the engine was at full throttle so the test should give reasonably comparable result. The maximum turbo boost pressure was 2245 mb.

Turbo performance at 4,200 m (13,800 feet) maximum boost pressure 2245 mb

As can be seen in the results, the maximum turbo boost pressure dropped from 2584 mb at 1000 m, to 2245 mb at 4,200 m, a drop of only 339 mb or 15%. It can be seen in the graphs that the turbo produced reasonably high boost-pressures at relatively low engine rpm. Therefore, the truck does maintain its performance even at high altitude in normal driving conditions and the 15% reduction in turbo boost (and therefore power) would only be noticed when using full throttle/engine power. To put this into perspective over the whole life of my truck, these are the time percentages spent at the various engine power percentages (data from ECU):

0 to 25% power = 31% of the time

25% to 50% power = 24% of the time

50% to 75% power = 26% of the time

75% to 100% power = 19% of the time

So the time that the engine has spent using above 85% power, is only a fraction of the 19% of time and is therefore not a concern for me. I am very happy with the performance at altitude. Even when driving through snow uphill off-road at altitudes above 4500 m, I did not require full power.

With Euro diesel engines at high altitude, it is also worth thinking about the case for a non-turbo engine. Sea level ambient pressure is approximately 1013 mb and at the time of my test at 4,200 m the ECU recorded the ambient pressure as 612 mb, so a non-turbo engine would have lost over 40% of its power!

You may find my page on fuel issues interesting too.